Tech info on MP - Fuel Delivery Systems

Find your vehicle...

Tuning Technical Information

We are increasingly getting inquiries from customers having problems with standard vehicles. They are being frustrated with New Car Dealers who are not listening to their complaints about their vehicles poor Economy or Performance. Dealers are finding themselves caught in the middle as manufacturers dumb down the test procedures which the dealers are only allowed to carry out. They are only permitted to replace what their Diagnostic Equipment determines, so faulty sensors sending incorrectly calibrated signals, result in the Diagnostic Equipment not seeing the real faults. These Pages are here to give you a better understanding of how your vehicle works & help you diagnose problems you are having with your vehicle.

Fuel Rail Pressure Sensor & Pressure Relief Valve

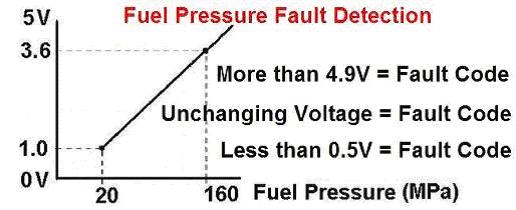

The Fuel Rail Pressure Sensor converts the pressure of the fuel in the Fuel Rail into a voltage signal of between 0-5v. Due to the pressures involved the sensor can go out of calibration, or the Pressure Relief Valve can leak too much fuel back to the fuel tank. The most common symptom of problems is if vehicle does not start or is difficult to start, another symptom is when vehicle has sudden flat spot on heavy acceleration at high rpm. If the vehicle gets a “High Fuel Pressure” fault code it will more likely be caused by water in the fuel, as water does not compress. The most common cause of failure of the High Pressure Pump is also normally Water in the Fuel, which is why most of these types of breakdown occur in remote areas. The quality of Fuel is vital to a CRD engine. If traveling in remote areas, it is a good idea to fill a jerry can from the same fuel pump, this way you have also got a sample of the fuel from the last station you visited.

Some companies also sell a plug to block off the Pressure Relief Valve, in this situation the pressure has no way to reduce back to safe levels, which will result in Engine Damage.

Fuel Injectors

Injector Boxes work one step behind the engine, which means they always have to look at the last signals they received, to then adjust the next signals trailing length. They can not predict when the Injection Pulses will change to longer or shorter. The Timing of these Pulses can only be modified by the Cam Angle Sensor or the MAP (Boost) Sensor as below.

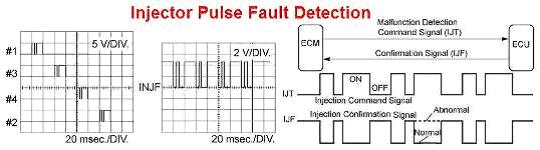

Some Injection Systems have an external Injector Driver Unit, which consists of transformers to convert low voltage Injection Signals from ECU, to High Voltage Signals for the Injectors. These Driver Units fail on the High Voltage side, but Scan Tools only detect faults on the Low Voltage side.

Injectors can leak fuel & are very expensive to replace, Mercedes recently switched from Bosch to using Delphi Injectors on their 4 Cylinder engines & found themselves plagued with Warranty issues caused by these Injectors. Landrover use Delphi on their 2.7L V6, but switched to Bosch for their new 3.0L V6. Although European Injectors are better quality, individual Injectors have different flow rates, sometimes these rates are not correctly set, resulting in noisy Injectors. For engine safety our TB-CRPD Tuning Box has been designed to have an Injector Variation Range Tolerance, once this range is exceeded the box will refuse to provide any further power gain. One of our customers complained that our box made no power gain on a vehicle. He then fitted a different brand of box which gave a power gain; the engine blew up 6 months later. He then realized our box was trying to warn him. He is now a good customer of ours!

Petrol EFI engines had only one Injection - Per Cycle – Per Cylinder. But some CRD engines now have 8 Injections – Per Cycle – Per Cylinder, so this means that just running at 1000rpm the Injector on just one Cylinder is switching - on & off - 4000 times per minute. So for a 4Cylinder engine this is 16000 Pulses per minute or 267 Pulses per second, just running at 1000rpm! These individual Pulses also vary in length according to what the Accel pedal is doing. With an Injector Tuning Box fitted, it is possible for Injector Pulses to be made too long so that they overlap, causing the Injector to “not switch off”. In this situation the vehicle can go into limp mode or have a “Fuel Leak” fault code as the ECU does not understand why the High Pressure pump has to work so hard.

Buy a Morepower Tuning Box for my vehicle.

Find out more about: